The clutch is the most important part of the transmission system of a vehicle. Can you imagine a vehicle, maybe a bike, scooter, car, or truck, without a clutch mechanism? No, without a clutch mechanism, we cannot imagine our vehicle moving here and there easily. Yes, we can imagine a vehicle without a clutch lever, but not without a clutch mechanism. Generally, our cars, buses, trucks, and bikes have disc-type clutches. In vehicles, there may be single-plate clutches or multi-plate clutches, as we can see. It depends on the vehicle type.

When you turn on your car’s ignition, after turning on the engine, you just need to press (or pull a lever in the bike) a lever, then activate first gear. Then you release the clutch slowly to move your vehicle. This lever, which plays an important role between engine starting and applying gear, is a clutch lever in manual-drive vehicles. It also plays an important role when the vehicle is running and we need to shift the gears from lower to higher or vice versa.

Page Contents

What is the clutch?

Definition of the Clutch: A clutch is a mechanism that allows the transmission of rotational motion from one shaft to the second shaft. Where the clutch is coupled between one and two shafts, which will be coaxial. We can also say that a clutch is a coupler because it joints two co-axial shafts. A clutch application is used where power transmission starts and stops frequently.

There are many types of friction clutches. Like Centrifugal clutch, cone clutch, disc clutch ( Single Plate clutch and Multi-Plate clutch), etc. Here, we will focus on the single-plate clutch.

What is a single-plate clutch?

In our vehicle, the clutch is located between the engine and gearbox. When the clutch is engaged (the lever is depressed or released), the rotational motion transmits from the engine shaft to the gear shaft. Then gears transmit the power to the propeller and then the wheels. When we push the clutch pedal (pull the lever), the clutch disengages, which stops the motion transmission from one shaft to the second shaft. While the engine shaft is still running. Generally, our vehicles have a plate or disc-type clutch. These disc-type clutches have two further types, i.e., single-plate clutch and multi-plate clutch.

The single-plate clutch is a type of disc-type clutch and an axial friction clutch.

Definition of Single Plate Clutch:

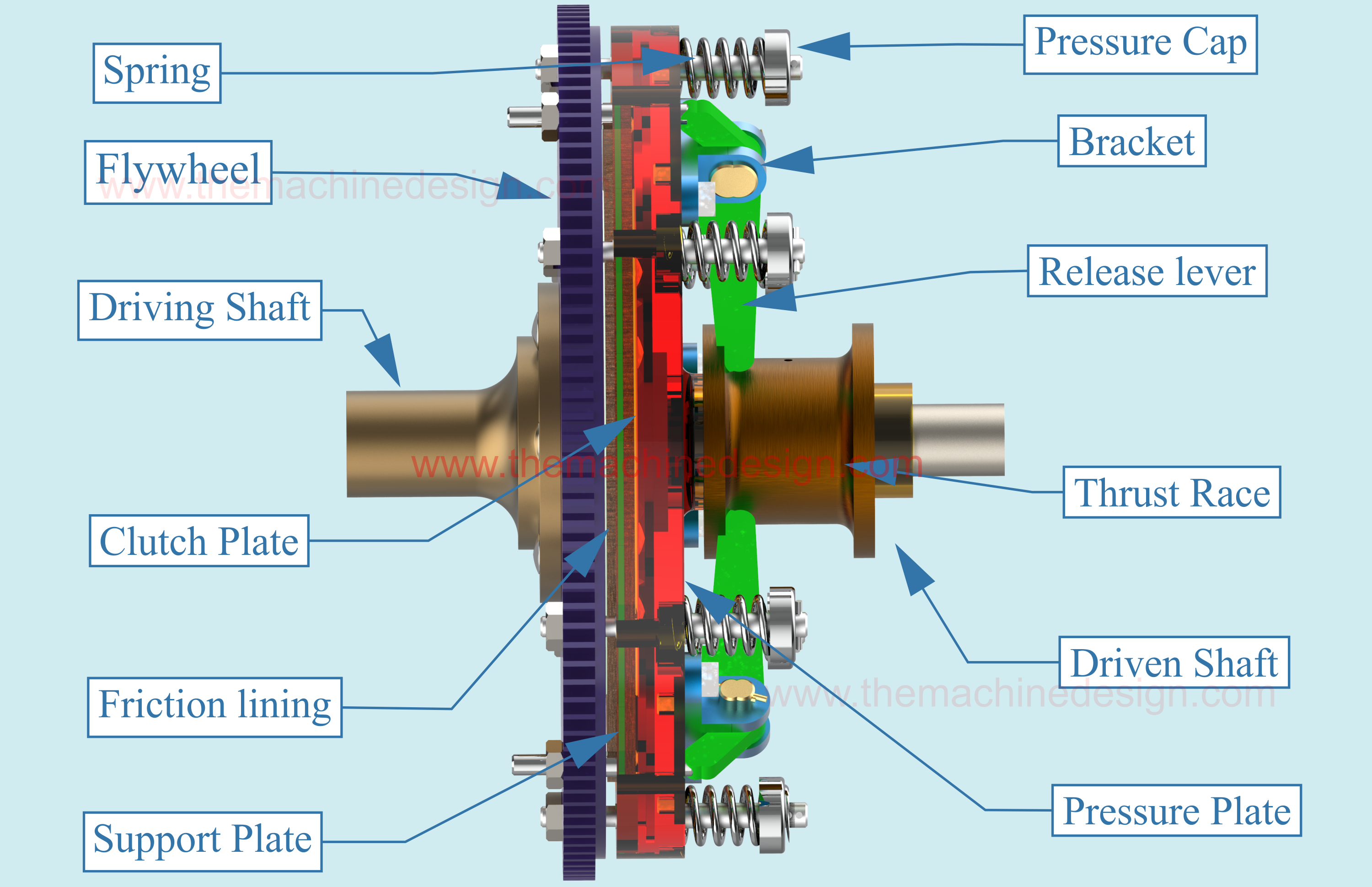

A single-plate clutch is shown in the image. A single-plate clutch has a single frictional disc, also known as a frictional lining. This frictional lining has two-sided frictional surfaces. It connects the crankshaft and driven shaft and transfers rotating motion. The whole unit has only one friction plate; that’s why it is called a single-plate clutch.

Before we read more about the clutch, we need to get familiar with two terms. These are engaged or disengaged clutches. When we start the engine, stop the vehicle, idle the engine, and shift up or down the gear, we disengage the clutch. This means when we push the pedal (or pull the lever), the coupling between the engine shaft and gear shaft will be disengaged by the clutch.

And when the vehicle runs continuously, at that time the clutch is in an engaged position.

Working Principles of a Disc Clutch:

The clutch principle is based on friction. When two rubbing surfaces come into contact with each other and unite by applying pressure to them, And if one surface rotates, the other one rotates as well. Here, rubbing action means friction is working between both surfaces. Here, the one surface that rotates first is a driving surface. And the other one that follows the first is a driven surface. The driving surface rotates as well after disconnection from driving. The friction between both surfaces depends on some factors (i). Working surface area (ii) and material’s friction coefficient (iii) Applied pressure to both surfaces.

Also Read:

- Hydrogen Fuel Cell Cars: A Closer Look at the Technology

- What is Lean Manufacturing?

- Three easy tricks drivers can save money on fuel.

How does a clutch work?

We have read in brief the working principle of a clutch in the above paragraph. Now we will read about the working method of a clutch. Let’s check out this link: Single Plate Clutch Working. In this animation, you can see basically how a single plate works.

In this video, you will see how a rotating disc (flywheel) rotates another co-axial disc with the help of friction. Hence, the driven disc rotates the splined shaft. This shaft provides motion to the gearbox.

Two co-axial shafts, one driving and another driven, are shown in the below image. The clutch connects both shafts. A flywheel is mounted on the end of the driving shaft, which has a bearing as well. Bearing’s inner race holds the fore-end of the driven shaft.

While the driving shaft rotates, due to the freedom in rotational motion with the help of the bearing, the driven shaft does not rotate. You can see it in the video.

Engagement of the clutch:

When force releases from the thrust race, spring pressure pushes the pressure plate towards to flywheel. This pressure plate applies pressure on the clutch plate, it is locked on the splined shaft. By sliding on the shaft, when it comes in contact with the rotating flywheel. Due to the friction clutch plate also rotates. The locked splined shaft also rotates with the clutch plate.

Disengagement of clutch:

The thrust race is pulled by the clutch lever wire or link. It pulls the long end of the release lever. The small end of the lever pushes the stud screwed on the flywheel. Since the release lever is mounted on a pressure plate with the bracket. It pulls itself towards to opposite to the flywheel as well as the pressure plate. This action disengages the clutch plate and flywheel.

The above image shows the disengaged clutch position.

Construction of a Single Plate Clutch:

A single plate consists of various small and major parts. Here we will do a study of some major parts. The above image demonstrates all of these major parts. The list of parts is as below:

Driving Shaft:

The driving shaft is an output shaft of the engine. Right side in the image.

Flywheel:

A heavy metal wheel is attached at the end of the driving shaft. It makes smooth power delivery from the engine to the gearbox. A whole clutch assembly is arranged with the flywheel.

Thrust race:

When an operator or driver pushes the clutch lever, It is the first part that acts in a clutch assembly. It slides on the driven shaft in order to clutch lever actions. The Clutch lever pulls the thrust race and consequently, it pulls the release lever.

Release lever and Bracket:

The release lever plays a very important role to transfer force from the clutch lever to the pressure plate. It is pivoted with a bracket and this bracket is fixed on the pressure plate. Lever’s one long end tangentially attached with the thrust race. And another end, which is short in length applies tangential force to the pin. When thrust race actuated by the clutch lever. Long end pulled by thrust race. Since the bracket pivots the lever, the short end pushes the pin. This pin fixed on the flywheel. That’s why this lever pulls the whole pressure plate subassembly apart from the flywheel.

Friction lining and clutch Plate:

Friction lining and clutch plate is the most important part of the clutch single plate clutch. The clutch plate is a metallic disc having friction lining both side faces. The clutch plate slides on the splined shaft between the flywheel and pressure plate. And the friction discs creates friction between flywheel and clutch plates. The pressure plate creates pressure on the clutch disc.

Pressure Plate:

The pressure plate creates pressure to couple the clutch and flywheel. We can see springs and pressure caps creates pressure on the pressure plate. This pressure is clamping pressure. When the driver presses the clutch lever, by the action of thrust race and release lever, this pressure plate pulled in opposite directions of the flywheel. At the same time, the clutch plate is displaced from the flywheel. And crank (driving) shaft and driven shaft starts to spin freely.

Driven Shaft:

The driven shaft is the output shaft of the clutch lever. This is the input shaft for the gearbox. Its one end (clutch side) is splined, so it is a splined shaft. This shaft transfers power to the gearbox.

Applications of a Single Plate Clutch:

Almost all know the clutch used in vehicles. But, single plate clutches are used where a large radio space area is available. So bigger vehicles like buses, trucks and cars have single-plate type clutches, but not possible to use in small vehicles like bikes, and scooters. In motorbikes and scooters, multi-plate clutches are used. Multi-plate clutch requires less radial space.

The single plate clutches have a larger surface area that dissipates heat easily. Hence, there is no required cooling oil. That’s why this is a dry-type clutch.

Also Read:

- Paddle Shifter in Automatic Transmission Car

- Three easy tricks drivers can save money on fuel.

- Sustainable Office Furniture: Creating an Eco-Friendly Workplace

Advantages and Disadvantages of a Single Plate Clutch:

Advantages:

- It has only one plate, so it operates easily and quickly.

- This mechanism has very little power loss.

- It has a larger surface area, it will dissipate heat quickly.

- It provides a very smooth operation during disengagement and engagement.

- Cheap and easy to manufacture.

Disadvantages:

- Torque transmission capacity is not enough good.

- Wearing and tearing properties are not really good.

- Higher maintenance is required.

- It requires a large space for assembling.

The single plate clutch construction working mechanism is something that all we need to understand about. Thanks for the information on this topic. Subscribed your blog.