Introduction:

Whether it’s automotive industry, plumbing, aerospace, and any manufacturing industry where machineries are present, all of them uses wrench as a fundamental tool for their maintenance work. Without them, the task of repair can not be imagined. If you don’t know what is wrench and its uses then you have arrived at correct place to know about it. Here we will discuss it definition, uses and types in brief. So, lets begin our research on Wrenches.

What is Wrench and Its Uses?

What is a Wrench?

We can define a wrench or spanner as a tool that is used to applying turning force on those fasteners which are rotating. If we talk in more simple words then a wrench uses turning force to open or closes nuts and bolts. Spanner is other name of the wrench by which it is known in many countries.

Common Uses of a Wrench in Mechanical Applications:

- Automotive Industry: wrenches are indispensable in vehical mainenance and repair. From changing tyres to working on engines, mechanics rely on them for efficient servicing.

- Plumbing Work: They are commonly used to install, tighten, and loosen pipes and fittings, making them crucial for plumbing professionals and engineers.

- Manufacturing & Machinery Maintenance: In industries with heavy machinery, wrenches are used for assembling and maintaining mechanical components to ensure smooth operation.

- Construction & Structural Work: Engineers and technicians use wrenches to assemble scaffolding, metal structures, and heavy-duty equipment, ensuring strong and secure fittings.

- Mechanical Engineering Projects: Wrenches play a key role in college mechanical projects, where students work on innovative designs, machines, and prototype development as part of their engineering curriculum.

- Houshold & DIY Repairs: Even in daily life, wrenches help with assembling furniture, tightening fixtures, and general home repairs, making them a versatile tool.

Also Read:

- Top Most Expensive Materials in the World

- Which metal is been used to make Cybertruck’s robust skin?

- Gas Springs Principle, Types, Applications

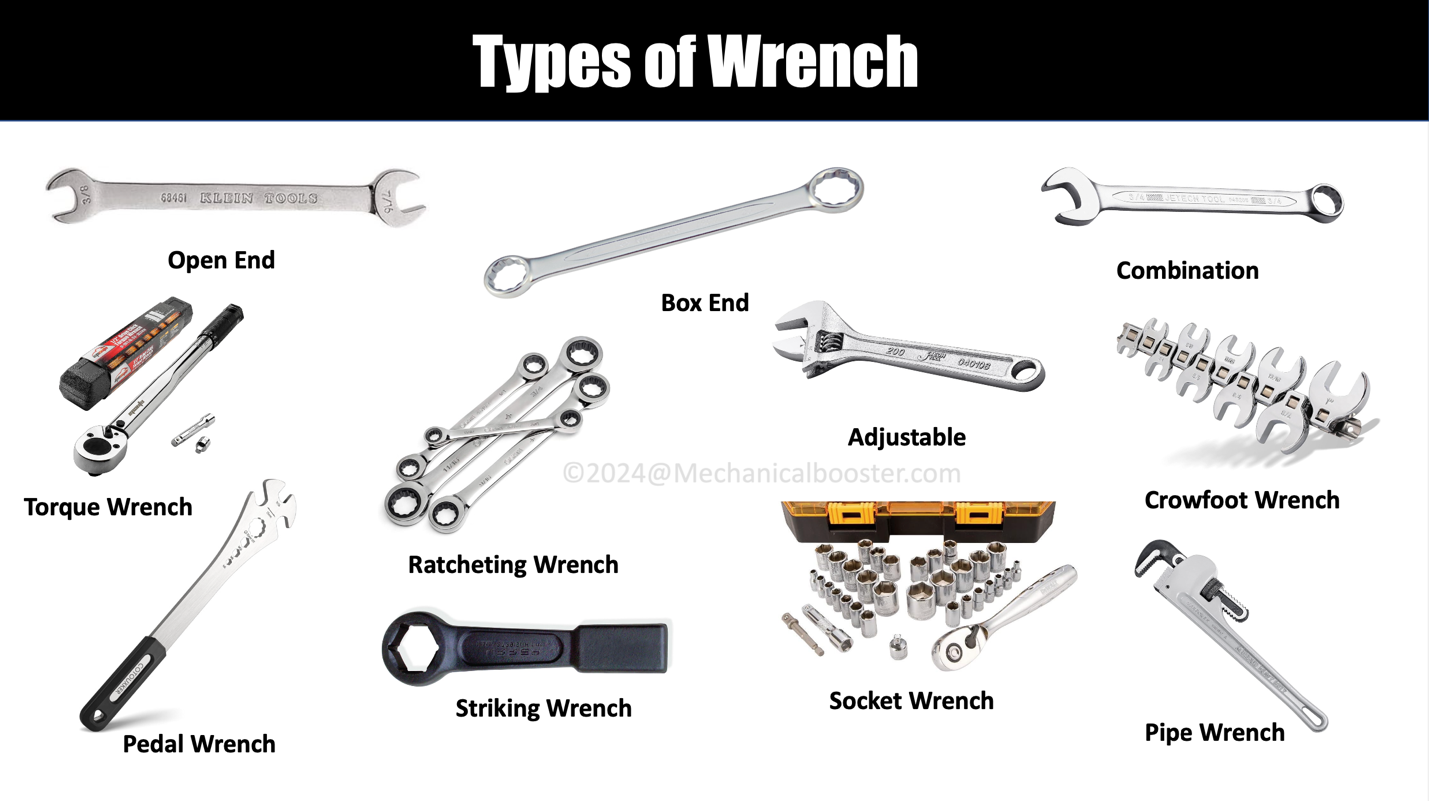

Types of Wrench

Open-end Wrench

In this wrench, both ends are open. It is used to open nuts and bolts where space is limited.

Box-Ended Wrench

Its both ends are closed. It is used to open nuts and bolts without slipping.

Combination Wrench

Its one end is open and other is closed. In this wrench, the open end is most commonly used to loosen the nuts and bolts and the box end or closed end, is used to complete loosening of nuts and bolts.

Torque Wrench

This wrench is used to tighten nuts and bolts, which requires predefined value of torque.

Adjustable Wrench

Adjustable wrenches are used to open a wide variety of nuts and bolts. Its size can be adjusted according to your need.

Crowfoot Wrench

Crowfoot wrenches do not have handle and they are made to fit with Ratchet. They are used to operate nuts and bolts which are in very tight space and other types of wrenches fail to work.

Ratcheting Wrench

These wrenches are used to open nuts and bolts without repositioning the wrench again and again. You have reposition it once then you can turn it to open and close the fasteners.

Pedal Wrench

Pedal Wrenches are used to operate pedals of bike or bicycle during its repair and transportation.

Pipe Wrench

These wrenches are made open and closes pipes in plumbing industries.

Striking Wrench

Striking wrenches are used to open nuts and bolts that get stuck and can not be opened by any other wrench. After setting the striking the wrench on the fasteners, you hammered its other end to open the stucked nuts and bolts.

Conclusion

For mechanical engineers and professionals, understanding the importance of a wrench is crucial. Mastering its use will not only enhance your skills but also prepare you for real-world mechanical applications. Whether in an automobile workshop, a manufacturing plant, or a construction site, a wrench remains one of the most fundamental tools in engineering.

Great breakdown of wrench types and their uses really clarified things! I have seen how choosing the right wrenches can save time on both DIY and professional setups.